LASER CUTTING LAB

Federica Poli, tel +39 0521 905766

federica.poli@unipr.it

Stefano Selleri, tel +39 0521 905763

stefano.selleri@unipr.it

Annamaria Cucinotta, tel +39 0521 905765

annamaria.cucinotta@unipr.it

Laser cutting lab

Our lab is equipped with solid-state and fiber laser for cutting of different materials, such as thin films, semi-conductor materials, plastics and alluminium sheets.

Our lasers can operate in both CW (Continuous Wave) and pulsed regimes, according to the material and the required processing, with emission wavelengths of 1030-1064 nm (IR) and 515 nm (green). Pulses duration between 600 ps and 100 ns, with repetition rate from 50 kHz to 250 kHz and average output power up to 30 W are available.

The laser cutting lab hosts fiber lasers based on both standard and Photonic Crystal Fibers (PCFs). Fiber lasers offer remarkable advantages with respect to disk or CO2-lasers. In particular, they have very high beam quality, with an M2-value close to 1. This allows for extremely precise cuts and for a reduction of the heat affected area. Moreover, fiber lasers can operate with very different output power levels without causing the beam to change its position and focus, thus allowing to obtain very smooth processing. Further advantages come from high processing speed and workable depth, high achievable output power, remote processing, the possibility to process highly reflective materials, low investment and maintenance cost, reliability and small packaging size.

The laser cutting lab is located at the Engineering and Architecture Department of the University of Parma, viale G.P. Usberti 181/A, I-43124 Parma. For information, contact:

Stefano Selleri, tel +39 0521 905763

stefano.selleri@unipr.it

Annamaria Cucinotta, tel +39 0521 905765

annamaria.cucinotta@unipr.it

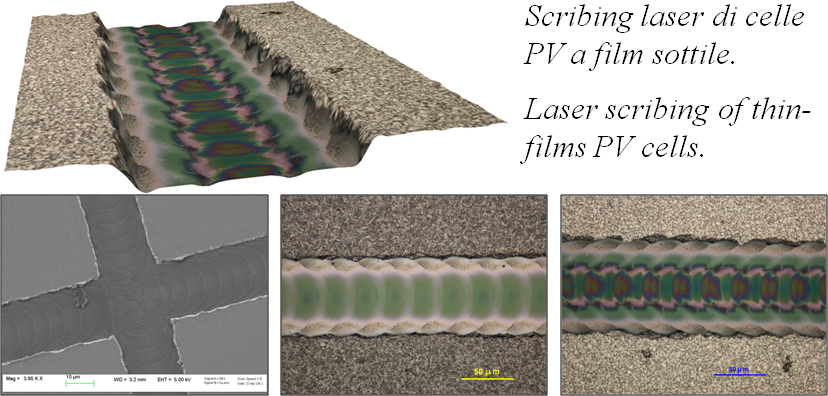

Thin-film solar cell processing

Laser scribing represents one crucial step for the production of the new generation thin films solar cells. The quality of the cuts on the PhotoVoltaic (PV) modules strongly depends on the parameters of the laser itself. Therefore, it is necessary to have the possibility to change the parameters of the laser radiation, such as pulse duration, shape, power and repetition rate.

Thin-film PV modules are made by a few layers which require three different scribing steps, in order to obtain monolithic interconnection of the cells. These steps are commonly named P1, P2 and P3. In CdTe/CdS devices, P1 removes TCO along parallel lines, which are typically separated by a few microns. The second laser scribing P2 removes CdS and CdTe along lines close to those made by P1. Finally, P3 removes all the layers except TCO. Through this process it is possible to obtain a module with cells extending on its whole length. The cell width is equal to the distance between two adjacent P1 cuts.

Plastic material cutting

Taking into account, for example, PVC/PVDC, the thermal vaporization of a very small volume of material and the small spot of the laser beam allow for cuts with width of about 100 micron, that is much less than the few millimeters that can be obtained with mechanical cutting. Moreover, a noticeable reduction of the ablated material quantity and a high processing speed can be obtained. The cutting speed depends on the material type and thickness, and on the used power.

Biological tissue cutting

Many chemical species are involved in light absorption in a tissue and their effect changes drastically with the radiation wavelength. The intensity of laser radiation and the concentration of chromofores in the tissues set the penetration depth for a given wavelength. A leading role is held by water, which represents the primary absorber in the infrared region.

Lasers can be effectively used also for hard tissues, such as in odontostomatology, where the primary chromofores are water, hemoglobin, hydroxyapatite and melanine.